ABOUT US

Enterprise Strength

- Categories:About Us

- Time of issue:2020-01-06 00:00:00

- Views:0

Powerful Enterprise Strength

We have advanced complete sets of heavy steel, light steel, net rack, pipe truss and box structure production equipment and production lines, with an annual production and processing capacity up to 80,000 tons and annual installation and construction area reaching over 300,000 square meters. Our major products include all kinds of light and heavy steel structures, various types of net racks, pipe trusses, box structures, H-shaped steel, Z-shaped steel, C-shaped steel, color steel tiles, metal contour plates, arc panel, rock wool EPS composite boards, etc.

Excellent Design and R&D Capabilities

A first-class engineer team composed of more than one hundred industry experts, senior engineers, doctors and masters provides one-stop service ranging from design to R&D and construction.

Use SPA200, ETABS \ SAFF \ MIDAS \ ANSYs and other advanced computational analysis software for structure design and optimization design;

Use special development software 3D3S, PKPM, MSTCAD on TAKLA / AUTOCAD platform for steel structure deepening design and detail design;

Perfect Product Quality

We extensively absorb professional talents and set up a set of strict management system. Scientific and standardized operating processes as well as advanced and innovative R&D technology lays a solid foundation for the long-term development of the enterprise.

Innovative design has been integrated into our life. It brings the product a new look and brings a sense of beauty and attraction different from that of traditional products. Owning to changes in consumers’ lifestyle, emphasis on individualism, self-expression, fierce market competition and demand of product differentiation, the enterprise upgrades product innovation design concept has become the trend. Xinlantian Huifeng looks far ahead and aims high, deeply realizes the importance of innovative design. We design and develop new products with innovative thinking and make every consumer enjoy beautiful life brought by innovation.

Perfect Quality Assurance System

1. Personnel Qualification Control

1) Professional technical personnel pass through training. We select experienced personnel.

2) Operators of main equipment shall receive both internal and external training, take appointment with certificates and shall be arranged in certain posts.

3) All kinds of welders hold qualification certificates of corresponding welding methods.

4) Both quality control and non-destructive testing personnel have obtained the qualification certificates issued by the industry.

2. Material Control Technology

1). According to the production characteristics of different steel factories, develop different retest and sampling methods and control raw material quality well.

2). Effectively improve the steel plates’ anti-lamellar tearing performance according to steel plate rolling principle.

3). Implement raw material texture color batch and factory numbering systems and track raw material quality, so that manufacturers and quality warranty booklets of raw materials can be traced from finished products.

3. Disassembling Technology of Complex Mechanism

1) Disassemble complex mechanisms reasonably according to the shrinkage and deformation principle of welding, effectively eliminating and reducing welding deformation and welding stress.

2) Reasonable disassembly can reduce welding deformation, so as to minimize mechanical and flame correction and effectively ensure physical properties of base metal.

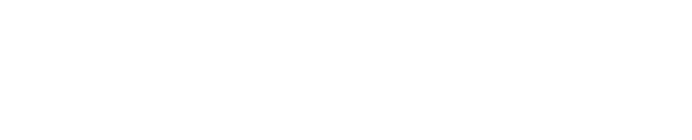

4. Welding Technology

1) Use double-wire and three-wire submerged arc welding, greatly improving the welding efficiency;

2) Use special welding process and process control, conduct high-strength thick plate welding and meet requirements of special engineering;

3) Groove design effectively avoids lamellar tearing and welding deformation in second half welding.

5. Welding Deformation and Contraction Control Technology

1) Arrange welding sequence reasonably, make use of deformation balance principle, and avoid and reduce welding deformation;

2) Use pre-deformation and anti-deformation to avoid and reduce welding distortion;

3) Adopt pre-release welding shrinkage according to experience, prevent size error due to welding shrinkage and ensure the site installation size.

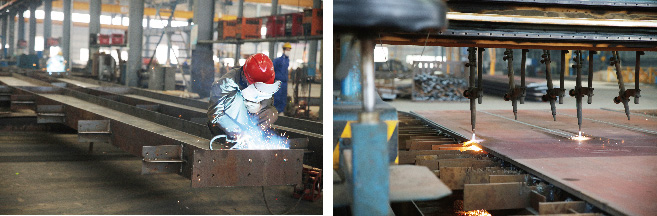

6. Hole Processing Technology

1) Make full use of advanced CNC machining equipment and improve group hole accuracy.

2) Adopt pre-release welding shrinkage according to experience to ensure the hole’s linking size accuracy;

3) According to the requirements of special structure, use heightening techniques through special process, eliminate accumulated errors during the processing process and ensure the site installation size;

4) Manufacturing of important structures should combine the actual installation size of the site; and the adoption of pre-adjusting value effectively eliminates production and installation errors.

7. Process Control Technology

According to the characteristics of special components, develop special control procedures, implement effective control to the whole structure processing process, and timely adjust blanking and assembly size.

Scan the QR code to read on your phone

CONTAC US

Headquarters: (86)0519-85868388

Shanghai: (86)021-59557953

Headquarters address: No. 10, Park West Road, Rulin Town, Jintan District, Changzhou City, Jiangsu Province

Email: binbin.liu@xltgg.com

Mobile terminal

Copyright © 2021 Changzhou Xinlantian Huifeng Steel Structure Co., Ltd. All Rights Reserved 苏ICP备16066896号-1

powered by:www.300.cn

Address: No. 10, Park West Road, Rulin Town, Jintan District, Changzhou City, Jiangsu Province

Phone: +86-519-85205555 / 85866388

Fax: +86-519-85210575 85862998

Contact: Geng Rongbo (13906119788)